User:Dingar/石雕

石头雕刻是使用雕刻的形式将粗糙的石头制作成特定形状的过程。由于制作材料的长期性,甚至可以发现最古老社会进行石头雕刻的证据。

History

[编辑]The oldest known works of representational art are stone carvings. Often marks carved into rock or petroglyphs will survive where painted work will not. Prehistoric Venus figurines such as the Venus of Berekhat Ram may be as old as 800,000 years, and are carved in stones such as tuff and limestone.

These earliest examples of stone carving are the result of hitting or scratching a softer stone with a harder one, although sometimes more resilient materials such as antlers are known to have been used for relatively soft stone. Another early technique was to use an abrasive that was rubbed on the stone to remove the unwanted area.

Prior to the discovery of steel by any culture, all stone carving was carried out by using an abrasion technique, following rough hewing of the stone block using hammers. The reason for this is that bronze, the hardest available metal until steel, is not hard enough to work any but the softest stone. The Ancient Greeks used the ductility of bronze to trap small granules of carborundum, that are naturally occurring on the island of Milos, thus making a very efficient file for abrading the stone.

The development of iron made possible stone carving tools, such as chisels, drills and saws made from steel, that were capable of being hardened and tempered to a state hard enough to cut stone without deforming, while not being so brittle as to shatter. Carving tools have changed little since then.

Modern, industrial, large quantity techniques still rely heavily on abrasion to cut and remove stone, although at a significantly faster rate with processes such as water erosion and diamond saw cutting.

One modern stone carving technique uses a new process. The technique of applying sudden high temperature to the surface. The expansion of the top surface due to the sudden increase in temperature causes it to break away. On a small scale Oxy-acetylene torches are used. on an industrial scale lasers are used. On a massive scale, carvings such as the Crazy Horse Memorial carved from the Harney Peak granite of Mount Rushmore and the Confederate Memorial Park in Albany, Georgia are produced using jet heat torches.

Stone sculpture

[编辑]

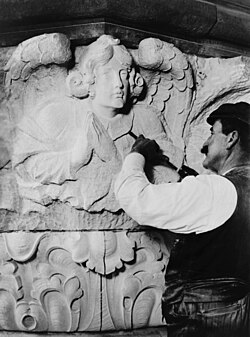

Carving stone into sculpture is an activity older than civilization itself. Prehistoric sculptures were usually human forms, such as the Venus of Willendorf and the faceless statues of the Cycladic cultures of ancient Greece. Later cultures devised animal, human-animal and abstract forms in stone. The earliest cultures used abrasive techniques, and modern technology employs pneumatic hammers and other devices. But for most of human history, sculptors used hammer and chisel as the basic tools for carving stone.

The process begins with the selection of a stone for carving. Some artists use the stone itself as inspiration; the Renaissance artist Michelangelo claimed that his job was to free the human form trapped inside the block. Other artists begin with a form already in mind and find a stone to compliment their vision. The sculptor may begin by forming a model in clay or wax, sketching the form of the statue on paper or drawing a general outline of the statue on the stone itself.

When s/he is ready to carve, the artist usually begins by knocking off large portions of unwanted stone. For this task s/he may select a point chisel, which is a long, hefty piece of steel with a point at one end and a broad striking surface at the other. A pitching tool may also be used at this early stage; which is a wedge-shaped chisel with a broad, flat edge. The pitching tool is useful for splitting the stone and removing large, unwanted chunks. The sculptor also selects a mallet, which is a hammer with a broad, barrel-shaped head. The artist places the point of the chisel or the edge of the pitching tool against a selected part of the stone, then swings the mallet at it with the strongest possible stroke. S/he must be careful to strike the end of the tool accurately; the smallest miscalculation can damage the sculptor's hand. When the mallet connects to the tool, energy is transferred along the tool, shattering the stone. Most sculptors work rhythmically, turning the tool with each blow so that the stone is removed quickly and evenly. This is the "roughing out" stage of the sculpting process.

Once the general shape of the statue has been determined, the sculptor uses other tools to refine the figure. A toothed chisel or claw chisel has multiple gouging surfaces which create parallel lines in the stone. These tools are generally used to add texture to the figure. An artist might mark out specific lines by using calipers to measure an area of stone to be addressed, and marking the removal area with pencil, charcoal or chalk. The stone carver generally uses a shallower stroke at this point in the process.

Eventually the sculptor has changed the stone from a rough block into the general shape of the finished statue. Tools called rasps and rifflers are then used to enhance the shape into its final form. A rasp is a flat, steel tool with a coarse surface. The sculptor uses broad, sweeping strokes to remove excess stone as small chips or dust. A riffler is a smaller variation of the rasp, which can be used to create details such a folds of clothing or locks of hair.

The final stage of the carving process is polishing. Sandpaper can be used as a first step in the polishing process, or sand cloth. Emery, a stone that is harder and rougher than the sculpture media, is also used in the finishing process. This abrading, or wearing away, brings out the color of the stone, reveals patterns in the surface and adds a sheen. Tin and iron oxides are often used to give the stone a highly reflective exterior.

Stone carving considerations

[编辑]

Soft stone such as chalk, soapstone, pumice and Tufa can be easily carved with found items such as harder stone or in the case of chalk even the fingernail. Limestones and marbles can be worked using abrasives and simple iron tools. Granite, basalt and some metamorphic stone is difficult to carve even with iron or steel tools; usually tungsten carbide tipped tools are used, although abrasives still work well. Modern techniques often use abrasives attached to machine tools to cut the stone.

Precious and semi-precious gemstones are also carved into delicate shapes for jewellery or larger items, and polished; this is sometimes referred to as lapidary, although strictly speaking lapidary refers to cutting and polishing alone.

When worked, some stones release dust that can damage lungs (silica crystals are usually to blame), so a respirator is sometimes needed.

Tools

[编辑]Basic stone carving tools fall into three types:

- Percussion tools for hitting - such as mallets, axes, adzes, bouchards and toothed hammers.

- Chisels for cutting - such as lettering chisels, points, pitching tools, and claw chisels. Chisels in turn may by hand held and hammered or pneumatic powered.

- Abrasives for erosion - such as carborundum blocks, drills, saws, grinding and cutting wheels, water erosion machinery and dressing tools such as French and English drags.

More advanced processes, such as laser cutting and jet torches, use sudden, high temperature to shatter the stone.

The use of chisels for stone carving is possible in several ways. Two are:

- The masons stroke, in which a flat chisel is used at approximately 90 degrees to the surface in an organised sweep. It shatters the stone beneath it and each successive pass lowers the surface.

- The lettering stroke, in which the chisel is used along the surface at approximately 30 degrees to cut beneath the existing surface.

There are many types and styles of stone carving tools, each Stone Mason or Artist will decide for themselves through training and/or experience which tools to use. Traditionalists will use manual Hand Tools only. Using Nylon Mallets, Beech Mallets, or many different Stone Carving Hammers, they will strike the top end of the tool, usually a Stone Chisel, with manual Force. The Chisels themselves can vary wildy.

- Lettering Chisels for small incisory strokes to create lettering detail in Monumental Masonry applications.

- Fishtail Carving Chisels are used to create pockets, valleys and for intricate carving, whilst providing good visibility around the stone.

- Masonry Chisels are used for the general shaping of stones, and as such are used by Stone Masons and artists.

- Stone Point Tools are used to rough out the surface of the stone.

- Stone Claw Tools are used to remove the Peaks and troughs left from the Stone Point tool.

- Stone Pitching Tools are used to remove large quantities of stone.

- Stone Nickers are used to Split stones by tracing a line along the stone with progressive strikes until the stone Breaks along the line.

Alternatively, they may use Pneumatic Power Hammers to make lighter work of things. Progresion in much faster with Pneumatic Stone Carving Tools. The Air Hammers (Such as Cuturi) place many thousands of impacts per minute upon the end of the tool, which would usually be manufactured or modified to suit the tool. This in effect creates the abiliy for the Mason/Artist to 'Shave' of the stone with ease. These tools provide a smooth and consistent stroke, so that control for Masons is much easier on large surfaces.

There are 2 main types of Stone Carving Chisel;

- Heat Treated High Carbon Steel Tools - Generally Forged

- Tungsten Carbide Tipped Tools - Generally Forged, Slotted, and Carbide inserts Brazed in to provide a harder wearing Cutting edged, that wont deform in use against even the toughest stones like Granite.